You have caught the bug! A friend with a great subwoofer (home or car) has shown you their setup. You have been browsing various online retailers and you think you can build it better, or cheaper. Perhaps you have been into audio for years and you are ready to up your game and DIY. Here is what you need to do before you start ordering parts and cutting wood.

1. BEGIN WITH THE END IN MIND

This is an old quote from Steven Covey. Focus on the result that you want, define the purpose of this project, and clearly understand why you are doing it yourself. Here are some things to think about.

- Is this for music or home theater? For home theater you need to reproduce bass frequencies that are below the normal human hearing range (20 HZ). For most types of music you don’t need to play as low.

- Is this for car or home? Car’s have less space to work with, but benefit from cabin gain. The design principles are the same, but the end goal is different.

- Do you want sound quality or do you just want to be loud?

- Are you going to build one subwoofer, or is this a lifelong hobby? This will make a difference later when start to build your tool collection.

- How are you going to “finish” the enclosure? Paint? Carpet? Veneer? Vinyl? Make sure you plan ahead so that the end project will look good, or at least tolerable.

2. IDENTIFY YOUR CONSTRAINTS

Like any other DIY project you need to understand the factors that are going to prevent you from creating the perfect subwoofer. The three most important constraints are:

- SPACE: Big bass requires large drivers in large enclosures and it is very important to put the driver in an appropriate sized enclosure. Putting a large driver in an undersized enclosure will give you horrible results. So start by understanding your available space. How much space do you have to work with? Will your wife let you put a big wooden box in the living room? How much room do you have under the seat in your four door pickup truck? How much of your car trunk are you willing to sacrifice?

- BUDGET: Most audio websites never talk about budgets, but they should. This hobby ain’t cheap. If you are looking at entry level gear, you can buy it cheaper than you can build it. You are only going to save money if you are trying to recreate a high end subwoofer, and only if you have access to the tools you need to do the job.

- POWER: If you are building a subwoofer for your car or truck there is one more thing to consider: POWER. Your alternator provides the juice while the car is running and your aftermarket subwoofer amplifier is going to compete with important things like headlights, spark plugs, and cooling fans. Every car is different, so every car will have a different maximum amount of power available for your subwoofer. Just remember that your car’s electrical system is not an infinite source of instant power and modern car electrical systems are more complex than you can imagine.

3. INVENTORY YOUR TOOLS

If you build things for a living (carpenter, electrician, etc) or if you are already an avid DIY’er you probably have the tools that you need. Otherwise you will need to start collecting tools. Don’t be afraid to start small, and start with cheap tools. Don’t get stuck into the “buy once cry once” mentality, this is just a marketing slogan designed to get you to spend more money than you need to. You don’t need a dedicated workshop loaded with industrial grade woodworking tools to build a 2 cubic foot box with a single hole in it. Here is a short list of basic tools that you will need to get started, along with links* to amazon so you can order the ones you don’t have.

- A workbench, a pair of decent sawhorses and some scrap wood is a good place to start. My first workbench was an old desk that somebody left on the side of the road.

- A jigsaw. This is the cheapest tool for cutting speaker holes. Don’t buy an expensive corded jigsaw. You will eventually want to upgraded to a cordless model.

- A circular saw. Again, don’t spend a lot on a corded model. You will eventually upgrade to a table saw and you will eventually want a cordless circular saw.

- A cordless drill. You can get buy with just one, and it does not have to be expensive. But life is easier if you have two. That way you don’t have to waste time swapping out a drill bit for a Phillips head bit while you are assembling the enclosure. Some speaker builders will glue and screw the box together. But there are plenty of other ways. You will, however, need to drill holes and drive screws to mount the driver in the enclosure.

- Clamps. Some speaker builders clamp and glue their entire enclosure, this works great. I use clamps as extra hands.

- A sanding block or a handheld electric sander. Again, you will upgrade to a cordless one eventually so don’t spend a lot of money on this item.

- An edge guide, so you can make straight cuts. Even if you just use a straight piece of wood you need an edge guide. I like the kreg rip cut.

- Wire crimpers, strippers, and cutters.

If you want to kick it up a notch here are some more advanced tools that will make life a lot easier:

- A brad nailer, either battery or pneumatic. Your enclosure will be held together with wood glue. Clamps, nails, and screws are just used to hold things together while the glue sets. My preferred method is to apply glue, clamp the pieces in place temporarily, drive in a few 18 gauge brad nails, remove the clamps and move on to the next piece.

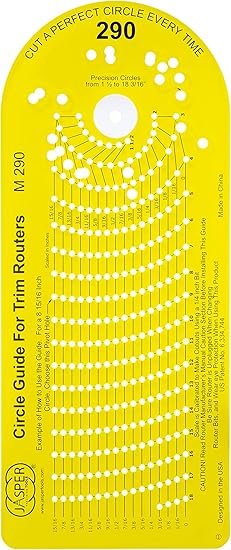

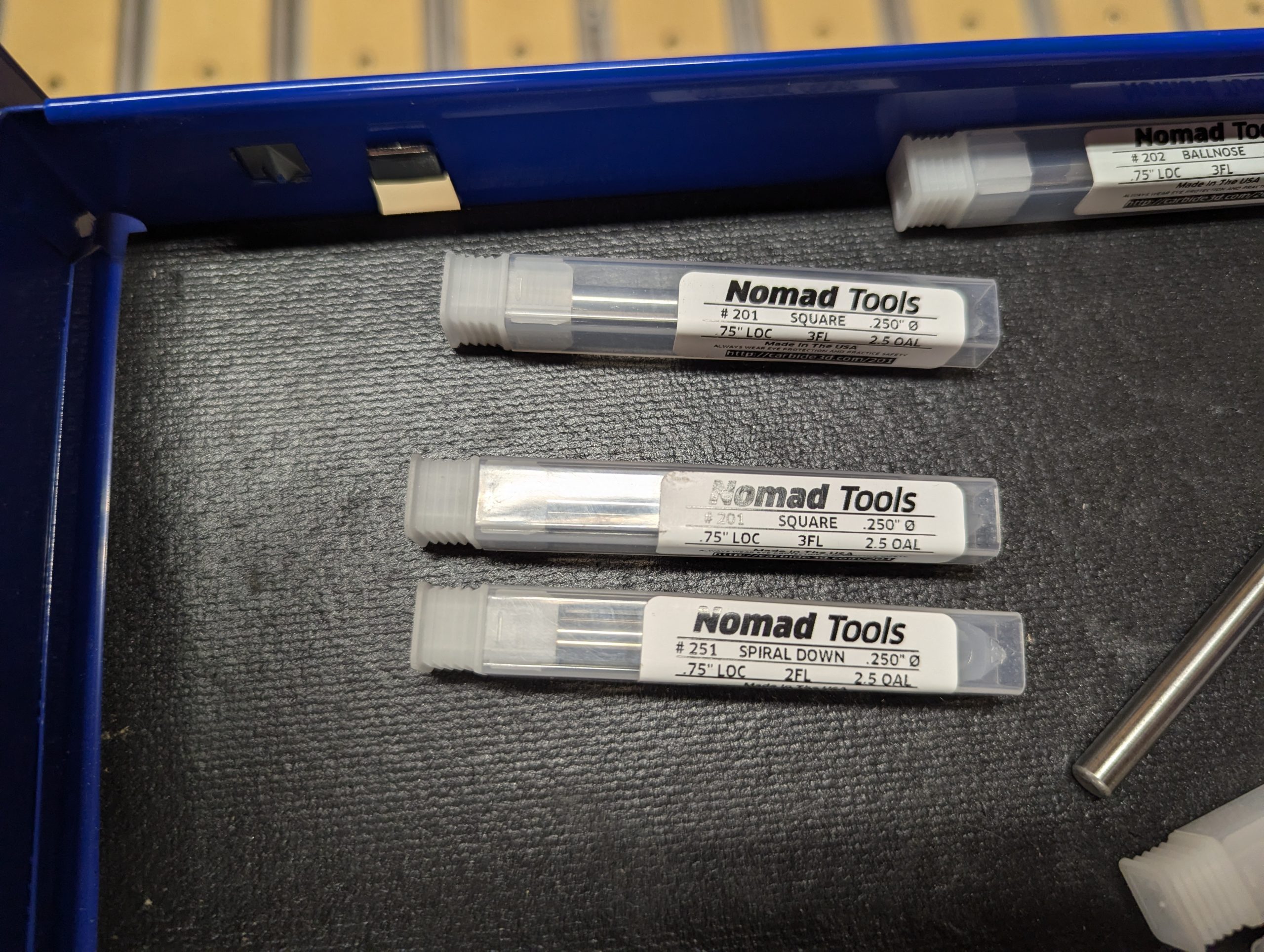

- A router with a circle jig. Cutting perfect circles with a jigsaw is hard. A circle jig on a router is almost idiot proof. You can also use the router to flush trim and round-over the edges. This will really improve your end product.

- A table saw.

- A torch for solder and shrink wrap

The DIY Audio Guy has a video showing how to build a box with basic tools:

You can find more information about tools here at Subwoofer University. Check out these tools for cutting perfect circles:

4. INVENTORY YOUR SKILLS

What do you know how to do? What are you good at and what is beyond your ability? Are you good at drawing? How about basic arithmetic? Do you know how to read a tape measure? Are you a professional cabinet maker? If you don’t have some basic DIY skills, don’t let that stop you. Instead, practice a bit. If you have never used a circular saw, then go get one, get some wood and start cutting. Don’t know how to solder? Go get a soldering iron and spend a few hours practicing. You will get better. Your first box will look like crap. So what? Go get some more wood and try again. Learn from your mistakes.

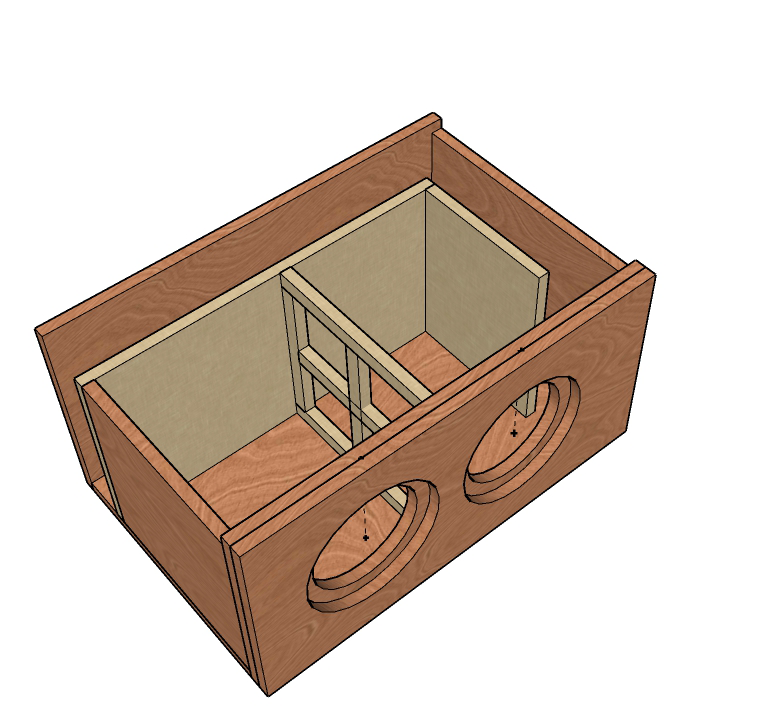

5. START SIMPLE, NOT SMALL

Large speakers are no harder to build than small speakers. In my experience small projects (boomboxes, small bookshelf speakers) are much harder to work with because of the tight space inside the enclosure. So don’t start with a 6.5″ woofer, start with a 12. But, keep it simple. Start with a sealed enclosure. If you start with a ported enclosure then build an existing design, or a kit, or stick to the manufacturer’s recommended specifications. Consider starting with a flat pack. Don’t try something complex until you have mastered something simple. Avoid exotic speaker coverings at first, then expand as your skill increases. Don’t start with plexiglass windows, exotic shapes, or advanced techniques. Sure, that stack-fab, fiberglass, passive radiator, eighth order bandpass you saw online looks nice. But you need start with a simple rectangular box with a single hole in it. After you can make a simple box look and sound nice then you can advance to the next level.

To learn more about the tools you need check out this video:

*Affiliate Disclaimer: Most of the links on this website are affiliate links. If you make a purchase the website owner may earn a small commission, at no cost to you. Affiliate links are how we pay the bills, so we appreciate it when you click on them and make a purchase.

Trusted Partners

I personally buy gear and tools from all of these companies, which is why I have affiliate deals with them. I may earn a small commission if you make a purchase.

Warning and Disclaimer!

This website, including all calculators, tools, and information, is provided “as is” without any warranty, express or implied, including but not limited to accuracy, completeness, or fitness for a particular purpose. The creators of this website are not responsible for errors on this site or mistakes made by users in applying the information. Using woodworking equipment, and other tools carries serious risks such as cuts, amputations, and hearing damage. Always wear appropriate PPE. Playing music at high sound pressure levels may cause permanent hearing loss, equipment damage, or violations of local noise ordinances. By using this website, you agree that you assume all risks and accept that the creators of this website are not liable for any damages, injuries, losses, or consequences—real or imagined—that may result from the use or misuse of this site.